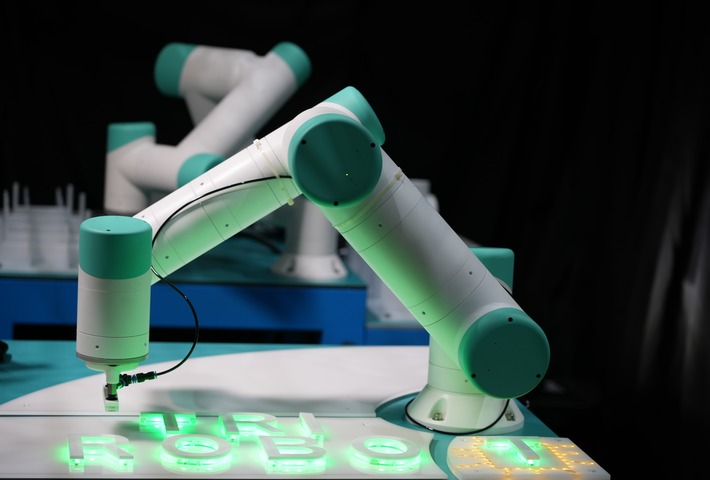

RoboTwin, developed by ITRI, adopts state-of-the-art AI and Sim2Real technologies to create a realistic simulation of a manufacturing factory where engineers and operators can experience realistic and immersive manipulations and interactions via specifically designed user interfaces. With RoboTwin, operators can receive coaching to resolve issues during the manufacturing process from an engineer via teleoperation capability. In addition, RoboTwin can be extended to various applications including multi-agent collaboration from various sites, remote troubleshooting, and maintenance via teleoperation. RoboTwin can be applied to diverse industries, such as semiconductors, machinery, and manufacturing. A leading Taiwan motor manufacturer TECO has adopted RoboTwin to create a virtual factory for increasing production efficiency.

AI and Sim2Real technologies are adopted to create a realistic simulation of a manufacturing factory.